PRODUCTS

Medium Density Fiberboard

Category

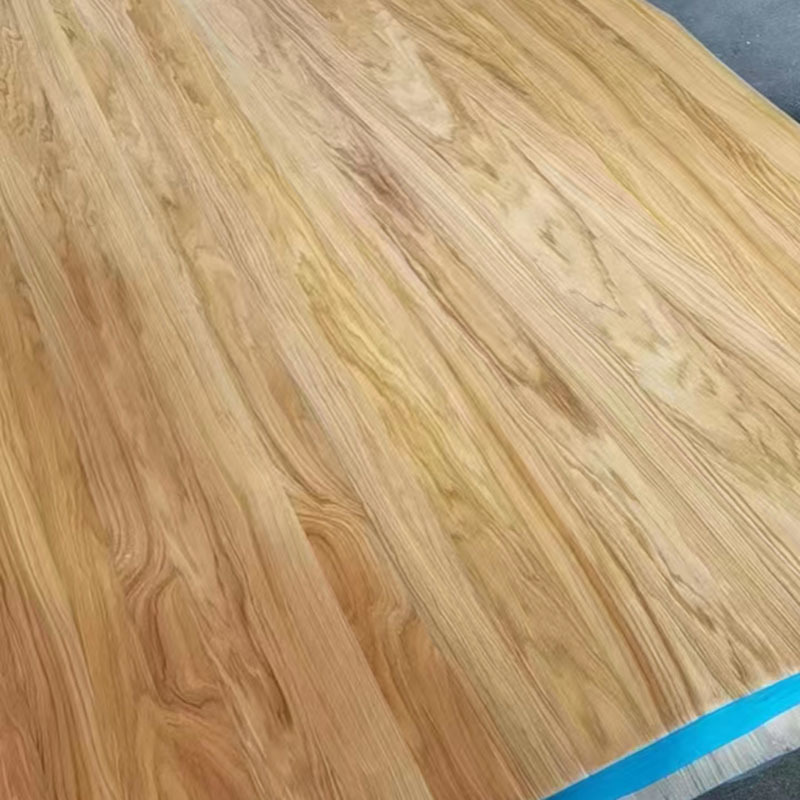

Description

MDF can be divided according to formaldehyde content: E0, CARB P2, E1, E2 grade MDF according to

Density can be divided into: low density board, medium density board, high density board.

MDF can be used for furniture, molding, milling and carving

HDF is mainly used as flooring substrate and template.

MDF can be divided into: moisture-proof MDF, fire-proof MDF, ordinary MDF, and waterproof MDF according to its usage.

What is MDF board?

The full name of MDF board in English is DensityFiberboard, abbreviated as mdf, referred to as medium fiber board. It is a man-made board made of wood fiber or other plant fiber, which is crushed, fiber separated, dried, coated with urea-formaldehyde resin or other suitable adhesive, and then hot pressed. Its density is generally in the range of 500-880 kg/m3, and its thickness is generally 1-18 mm.

A kind of medium density fiberboard (man-made board), the logs are degreased and debarked, crushed into wood chips, and then shaped by high temperature and pressure, the density is very high, so called MDF. its surface is often affixed with trimethyl ammonia or veneer and other finishes.

The advantages of MDF board

1, excellent physical properties, uniform discharge, no dehydration problems, no moisture deformation.

2, the surface of the trimethyl ammonia finish has moisture, corrosion, wear resistance, high temperature resistance, etc., without post-treatment, low formaldehyde content.

3、Since all the raw materials are very fine wood powder, from the perspective of moisture resistance, a piece of MDF soaked in water will expand like bread.

What are the classifications of MDF?

1. Low density name: soft fiberboard

(1) density standard: density below 0.4g/cm3

Weight and other exchange: equivalent to less than 400KG per cubic meter

(2) material characteristics: light weight, large porosity, good heat insulation and sound absorption, the

(3)Sheet characteristics: After special treatment, we can get light fiber board with more pores, which has adsorption performance and can be used to purify air.

(4) Product use: mostly used as covering materials inside public buildings.

2. Medium density name: medium density fiberboard

(1) density standard: 0.4g/cm3-0.8g/cm3 between (generally in 0.7g/cm3 or so)

Weight and other exchanges: equivalent to 400KG-800KG per cubic meter

(2) Material characteristics: uniform organization, moderate density and strength, good reworkability.

(3) Product use: wide range of product thickness, wide range of uses, such as furniture materials, TV shell materials, etc.

3. High density name: Hardboard

(1)Density standard: density above 0.8g/cm3

Weight and other exchange: more than 800KG per cubic meter

(2) Material characteristics: heavy mass, difficult to process

(3)Product use: The product thickness range is small, mostly used in construction, ships, vehicles, etc.

When buying MDF, you should touch the surface of MDF by hand. The smooth surface of the medium fiber board quality is good. If it feels astringent, it means that the processing is not in place, and the hard and brittle board must be inferior.

The 7 characteristics of MDF board

1, uniform internal organization, moderate density, good dimensional stability, small deformation.

2, static flexural strength, internal bonding strength, elastic modulus, board surface and board edge grip screw force and other physical and mechanical properties better than particle board.

3、The surface is flat and smooth, which is convenient for secondary processing. It can be affixed with rotary cut veneer, sliced veneer, painted paper, impregnated paper, and also can be directly painted and printed for decoration.

4、The width of MDF is large, and the thickness can be changed within 2.5~35mm, so it can be produced according to different purposes.

5, mechanical processing performance is good, sawing, drilling, tenoning, milling, sanding and other processing performance and wood similar, some even better than wood.

6, easy to carve and mill into a variety of profiles, shapes of furniture parts. After processing, the shaped edges can be directly painted and other trimming treatment, without sealing edges.

7、Water repellent, flame retardant, preservative and other chemicals can be added in the production process of medium fiber board to produce special-purpose medium fiber board.

Keywords:

询价

Is located in the logistics city of Shandong Province - Linyi City, Yitang Town Industrial Park is an international wood industry company integrating production, sales, processing and trade.

CONTACT US

+8617661668329

+8617661668329

+8617661668329

+8617661668329

monica@sdyzwood.com

monica@sdyzwood.com

Yitang Industrial Park, Yitang Town, Lanshan District, Linyi City, Shandong Province

Yitang Industrial Park, Yitang Town, Lanshan District, Linyi City, Shandong Province

Copyright © 2022 Shandong Yuanzuo All Rights Reserved. Powered by www.300.cn SEO

+8617661668329

+8617661668329